Our Abilities

Kerem Makine specializes in rim mold design, engineering and production. We have more experience trim moldings from other producers in Europe and Turkey and are among the world's leading supplier of trim moldings. We are committed to continually improving wheel mold processes and designs. We also work with our strategic alliance partner in automotive tooling and casting solutions to add value while bringing new efficiency to aluminum wheel casting, including material savings, weight reduction, metal reduction in the "T" section and wheel flash reduction. As Kerem Makine, we are always at the forefront of adopting new information and technology. Thanks to the fully integrated 3D CAD/CAM system, our experienced mold designers and engineers can turn a highly complex product design into a delicate finished product.

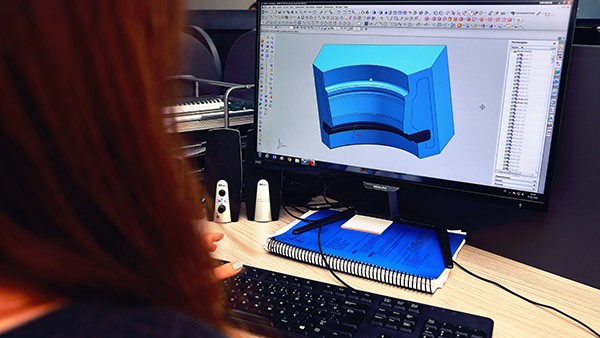

Engineering Project

For us, every new project means a new production process. Our engineers perform the modeling, design and analysis stages in the most accurate way during the project process. We turn every project we take into high performance and durable molds with our strong relations with our customers, our experience in production, our engineers who are experts in rim mold and the latest programs. The project team reports the entire process and a production ID for that product is generated, thus it enables faster and trouble-free production for new orders.

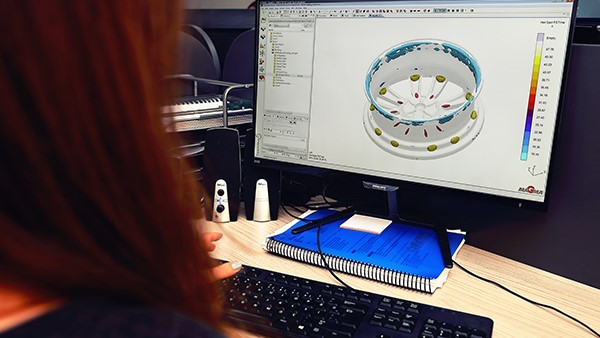

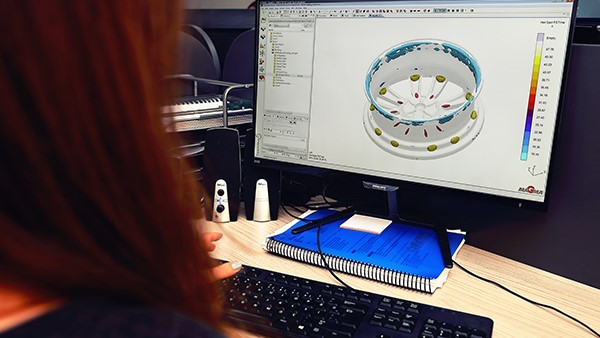

Analysis

After each project is modeled and designed, it is subjected to casting tests with current programs. By making the necessary interventions, the product reaches the highest performance and the problems that may occur during the production phase are prevented.

Production Machining

We closely follow the production techniques and technologies in the world. While ensuring the development of our production personnel with continuous trainings, we are keeping pace with the era both technologically and technically by realizing the technological investments we need.

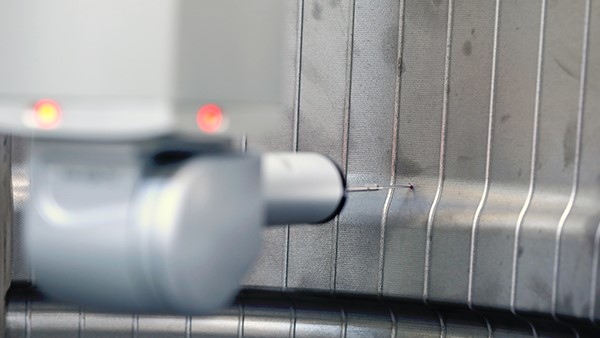

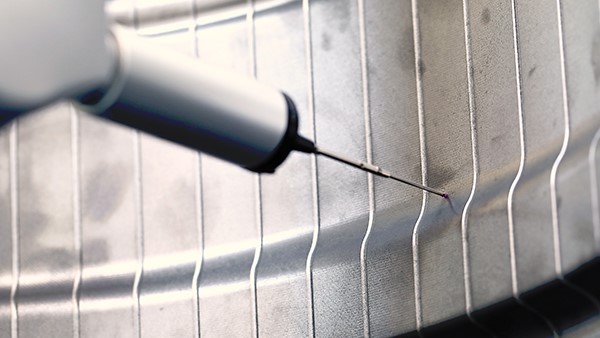

CMM

The finished product is measured with CMM device. The resulting data is compared with the design from the customer and zero defect production is completed.